Products

Deboom Energetic Graphene Engine Oil Additive for Marine Engine,Improving Engine Performance and Fuel Consumption Efficiency

How Energetic Graphene Works?

Friction and wear between mechanical parts widely exist in mechanical systems. Engine is the same.Reducing friction and wear between engine parts is critical to improving engine efficiency and service life. Not only does friction consume a lot of energy, but it can also lead to premature failure of parts. Therefore, the key to solving these problems lies in effective lubrication technology. By using advanced lubrication methods, the service life of the engine can be extended while reducing energy consumption.

Graphene, as the ideal nanomaterial to improve tribological performance, enhances the lubricant properties of base engine oil. Graphene possesses remarkable lubricating properties, which make it a promising material for various industrial applications.One of the key features of graphene that contributes to its lubricating properties is its high surface area-to-volume ratio. Graphene is a single layer of carbon atoms arranged in a honeycomb lattice structure. This structure provides an exceptionally large surface area, allowing graphene to form a strong and stable lubricating film on the surfaces of interacting materials.

In summary, graphene's lubricating properties stem from its high surface area, smooth surface, load-bearing capabilities, thermal and chemical stability, low friction coefficient, and high wear resistance. These unique characteristics make graphene an attractive candidate for developing advanced lubricants that can significantly improve the performance and durability of various engineering systems.

When engine is started, graphene nano particles enable penetration and coating of wear crevices (surface asperities) forming a thin protective film between metal parts of moving pistons and cyliners.Due to the very small molecular particles of graphene, it can generate a ball effect during friction between the cylinder and the piston,transforming sliding friction between metal parts into rolling friction between graphene layers. friction and abrasion are greatly reduced and powder is enhanced, consequently saving the energy and improving the fuel consumption efficiency. Besides, during the circumstance of high pressure and temperature, graphene will attach onto the metal surface and repair the wear of the engine(carburizing technology), which will prolong the engine service life. When the engine operates at peak efficiency, it leads to a decrease in carbon emissions to the environment as well as a reduction in noises and vibrations.

Timken Friction Test

Test shows the friction is greatly reduced and the lubrication effect is significantly improved after energetic graphene is used in the oil.

Application

Vehicles with gasoline engine.

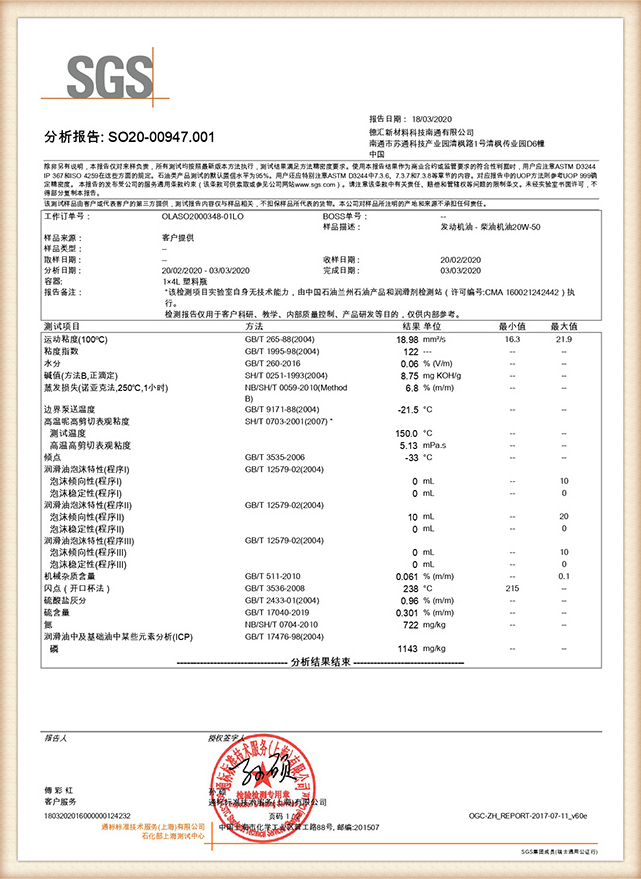

Certificates

CE, SGS, CCPC

Why Us?

1.29 Patents Owner;

2.8 Years' Research on Graphene;

3.Imported Graphene Material from Japan;

4.The Sole Manufacturer in the Industry of China;

Obtaining the Transportation Energy Saving Certification.

Frequently Asked Questions

1.Are you manufacturer or trading company?

We are a professional manufacturer.

2.How long has your company been in this industry?

We have been in the research,manufacturering and sales for more than 8 years.

3.Is it graphene oil additive or graphene oxide additive?

We use purity 99.99% graphene, which is imported from Japan. It's 5-6 layer graphene.

4.What is MOQ?

2 bottles.

5.Do you have any certificates?

Yes, we have CE, SGS, 29patens and many certificates from China top testing agencies.